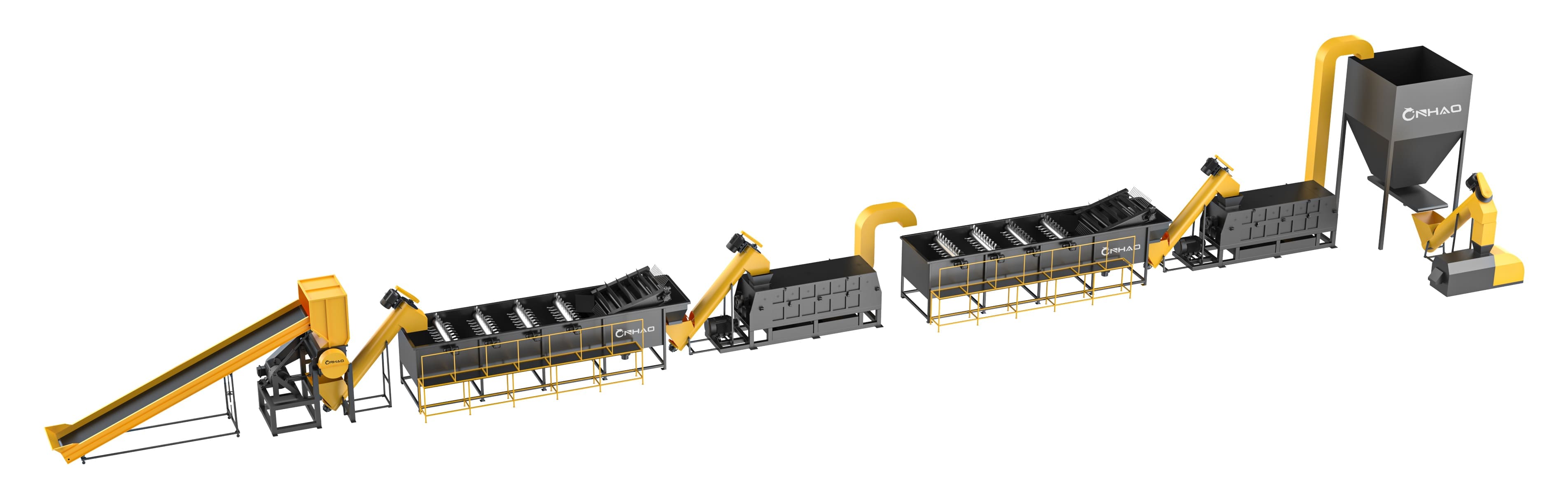

Streamline Eco Tech’s Plastic Film Wash line: Utilizing multi-stage physical washing technology integrated with intelligent water management systems, It efficiently remove soil, pesticide residues, and other contaminants from agricultural film. The process delivers high-purity plastic flakes ready for pelletization and high-value recycling.

Core Equipment & Function Analysis

◦ Function: Pre-shreds baled film into 10-40mm flakes(Customizable mesh size).

◦ The rotor, characterized by high-speed rotation and acute blade edges, is generally deployed for secondary shredding operations. During operation, strict precautions must be taken to prevent any metal objects or hard foreign materials from entering the crushing chamber.

- Friction Washer:

◦ Core Function: Intensively strips adhered contaminants.

◦ Film flakes + heated water form high-turbulence (1200 RPM) vortex → High-frequency inter-flake friction → >95% soil detachment efficiency.

- Rinsing Tank:

◦ Function: Secondary rinsing and impurity sedimentation.

◦ Unique Structure:

→ Hexagonal tank design: Induces circulating currents to enhance rinsing

→ Sloped silt hopper (V-shaped design at tank bottom): Automatically collects settled sediments

- Centrifugal Dewatering Unit:

◦ Performance: Residual moisture ≤5% ; Produces high-dryness flakes optimized for storage, transport, or direct extrusion.

- Cyclone collection

◦ Efficiently removes dust and labels while collecting processed material.

Modular Design Enables Customizable Integration (Compatible with various PE Film: Greenhouse Cover, Mulch Film, Silage Wrap etc.)

- Chain Conveyor:

◦ Function: Uniform feeding of baled material to shredder.

◦ Features: Adjustable chain pitch prevents entanglement; Integrated metal detector removes ferrous/rubble contaminants to protect downstream equipment.

- Trommel Pre-Washer:

◦ Function: Primary screening/segregation of large debris & fines.

◦ Design: Dual-layer drum screen → Outer Ø50mm removes rocks/sticks; Inner Ø10mm removes fine sand/silt.

- Hot Wash Tank:

◦ Function: Dissolves greases, waxes, and adhesive labels/stickers.

◦ Process: The innovative thermal wash stage precisely dissolves stubborn grease, waxes, and adhesive labels, significantly reduces downstream cleaning burden.

- Closed-Loop Water Recycling System:

◦ Process: Rinse effluent → Settling basin → Multi-stage filtration (Sand + Activated Carbon) → Reuse in main washing circuit.

◦ Sustainability Benefit: >40% water consumption reduction vs. open-loop operations.

When Visibility Fuels Environmental Governance

Streamline Eco Tech transforms uncontrollable agricultural plastic pollution into precision-engineered industrial solutions through our advanced film washing lines. Our visualization technology not only monitors processes, but also redefines trust standards for circular agriculture – enabling every recycled film to carry verifiable green value.

Choosing our agricultural film recycling solution means empowering resource circulation through technology, jointly advancing sustainable green agriculture. Consult our experts to obtain custom solutions and commence a new chapter in film recycling!