Maailmanlaajuisen ajoneuvokannan kasvaessa vuosittain romutetaan kymmeniä miljoonia autoja, jotka sisältävät suuria määriä talteenotettavia sisustusmateriaaleja. Sisätilojen kehittyessä kohti älykkäitä, elektronisia ja integroituja malleja niiden lisääntyvä monimutkaisuus asettaa uusia haasteita kierrätykselle ja käsittelylle.

Näiden kysymysten ratkaisemiseksi, Streamline Eco Tech on kehittänyt innovatiivisen monivaiheinen silppuritekniikka ja räätälöityjä kierrätysratkaisuja. Nämä järjestelmät auttavat maailmanlaajuisia romuajoneuvopurkamoita parantamaan materiaalin talteenoton tehokkuutta ja vähentämään samalla käsittelykustannuksia 15-25%, mikä antaa uutta vauhtia autojen kiertotaloudelle.

Autojen sisätilojen maailmanlaajuinen konteksti ja nykytilanne

Autojen sisätilat ovat kehittyneet yksinkertaisista rakenteista erittäin kehittyneisiin järjestelmiin. Varhaiset mallit periytyivät vaunujen piirteistä, ja niissä oli näkyviä metalliniittejä ja käsittelemättömiä puurunkoja.

Autoteollisuuden kehittyessä sisätilojen muotoilu koki useita muutoksia: hienosäätöä vuoden 1959 tienoilla, sähköistämisen alku vuonna 1965, ergonomiaa ja mukavuutta vuonna 1998 ja vuodesta 2007 lähtien integroitua ja teknologista muotoilua sähköistämisen ja autonomisen ajamisen myötä.

Nykyaikaiset sisätilat muodostavat nykyään suuren osan ajoneuvon arvosta. Tyypillinen henkilöauto sisältää 200-300 kg sisustusmateriaalit, mukaan lukien kojelaudat, istuimet, ohjauspyörät, ovipaneelit, verhoilut ja matot.

Nämä materiaalit - muovista, kankaista ja nahasta komposiitteihin - ovat erilaisia ja monimutkaisia. Sähköajoneuvojen älykkäät näytöt ja anturit monimutkaistavat kierrätysprosesseja entisestään.

Tärkeimmät sisustustyypit ja kierrätyshaasteet

Autojen sisätilojen osat voidaan luokitella seuraavasti:

- Mittaristojärjestelmät: Kojelauta, hansikaslokero ja keskikonsoli - pääosin valmistettu muovista. PP/ABS tekniset muovit.

- Istuinkokoonpanot: Päällysteet, vaahdot ja kehykset, jotka koostuvat kankaasta, nahasta, polyuretaanivaahdosta ja metallirakenteista.

- Ovipaneelit: Sisältää paneelin rungon, käsinojan ja säilytystaskut - pääasiassa muovia ja kangasta.

- Kattojärjestelmät: Kattoverhoilut, aurinkosuojat ja kattoluukun osat - usein komposiittikuiduista valmistetut.

- Matot ja akustinen eristys: Lattiamatot ja äänenvaimennustyynyt, jotka on valmistettu tekstiileistä ja polymeerivaahdoista.

Kierrätyshaasteisiin kuuluvat:

- Materiaalien monimuotoisuusmikä vaikeuttaa lajittelua ja erottelua;

- Monimutkaiset liitosmenetelmät(liimaus, hitsaus, klipsit), jotka estävät tehokkaan purkamisen;

- Vaarallisten aineiden esiintyminen, kuten raskasmetalleja, jotka aiheuttavat ympäristöriskejä, jos niitä käsitellään väärin.

Sisäsilppureiden päätyypit ja tekniset ominaisuudet

Erilaisia murskausjärjestelmiä on kehitetty vastaamaan erityisiin kierrätysvaatimuksiin:

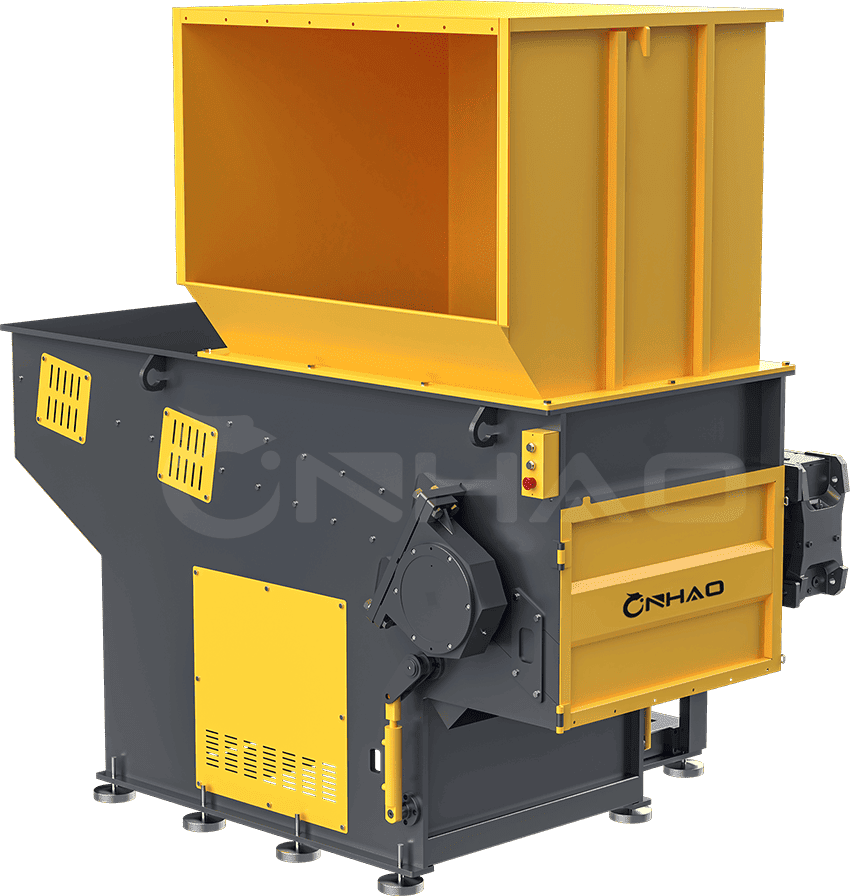

Single Akselisilppuri

Hydraulisella työntölaitteella ja säädettävällä tuotoskoolla varustettu silppuri kestää sotkeutumista ja tukkeutumista. Se käyttää moottorikäyttöistä roottoria sisäisten muovien murskaamiseen pieniksi palasiksi, mikä on ihanteellista kevyille polymeerimateriaaleille.

Double Akselisilppuri

Käyttää kahta vastakkain pyörivää terää tehokkaaseen leikkaamiseen ja repimiseen. Kietoutumisenestosuojalla ja maahantuoduilla sähkökomponenteilla varustettu laite tarjoaa suuren vääntömomentin, vakaan toiminnan, alhaisen melun ja energiatehokkuuden - soveltuu suurikokoisille ja jäykille komponenteille.

Multi Vaiheen silppurijärjestelmä

Yhdistää karkean ja hienon murskauksen vaiheittaiseksi prosessiksi, johon kuuluu tyypillisesti kuljettimia, pölynkerääjiä ja ohjausjärjestelmiä. Tämä kokoonpano mahdollistaa automatisoidun toiminnan, tehokkaan materiaalin erottelun sekä pienemmät melu- ja pölypäästöt.

Taulukko 1. Yleisten sisäsilppureiden suorituskykyvertailu

| Tyyppi | Kapasiteetti | Lähtökoko | Sovellettavat materiaalit | Tärkeimmät edut |

| Yhden akselin silppuri | 5-8 t/vrk | 20-40 mm | Muovit, nahka | Vähän huoltoa, häirinnänesto |

|

Kaksoisakselinen silppuri |

10-15 t/vrk | 20-60 mm | Tekstiilit, komposiitit, jäykät osat | Suuri vääntömomentti, tehokas silppuaminen |

|

Monivaiheinen silppurijärjestelmä |

15-25 t/vrk | Mukautettavissa | Kaikki sisustusmateriaalit | Korkea talteenottoaste, automaatio |

Monivaiheinen kierrätys- ja materiaalin talteenottoprosessi

Autojen sisätilojen kierrätys monivaiheisen murskauksen avulla on järjestelmällinen prosessi, joka mahdollistaa arvokkaiden materiaalien talteenoton.

- Esikäsittely- Ajoneuvot puretaan akkujen, moottoreiden ja polttoainesäiliöiden poistamiseksi, minkä jälkeen niistä irrotetaan sisäosat, kuten istuimet ja kojelaudat.

- Silppuaminen ja erottelu- Materiaalit murskataan useissa vaiheissa, minkä jälkeen suoritetaan magneettinen, ilma- ja pyörrevirtaerotus metallien, muovien ja kumien erottamiseksi.

- Materiaalin uudistaminen- Lajitellut materiaalit jälleenkäsitellään: muovit pestään, sulatetaan ja pelletöidään. kierrätetty hartsi, kun taas kankaat ja nahkakuidut käytetään uudelleen akustisissa materiaaleissa tai täytemateriaaleissa.

Teollisuuden testit osoittavat, että monivaiheisella silppuamisella voidaan saavuttaa seuraavat tulokset yli 90% materiaalin talteenottoerityisesti muovien ja metallien osalta.

Streamline Eco Techin räätälöidyt ratkaisut

Laaja kokemus kiinteän jätteen käsittelystä, Streamline Eco Tech tarjoaa räätälöityjä ratkaisuja autopurkamoille.

Sen modulaarisissa monivaiheisissa järjestelmissä yhdistyvät esilajittelu-, murskaus- ja hienoerotusyksiköt, jotka mahdollistavat tehokkaan ja skaalautuvan resurssien talteenoton. Jokaisessa järjestelmässä on käärimistä estävät terät ja älykäs ohjaus vakaata ja turvallista toimintaa varten.

Valinnainen visuaalinen etävalvonta mahdollistaa reaaliaikaisen toiminnan valvonnan, minimoi seisokit ja parantaa läpimenoaikaa.

Tulevaisuutta ajatellen, kun "sisätilojen kierrätys-regenerointi-sovellus" Streamline Eco Techin ratkaisut auttavat yhteistyökumppaneita vähentämään resurssien kulutusta ja hiilidioksidipäästöjä, mikä tasoittaa tietä aidosti kiertävälle autotaloudelle.

Kiinassa yksi Streamline Eco Techin koko järjestelmän käyttöön ottanut purkamo tuottaa nyt silputtujen sisätilojen muovirakeista kierrätysmuovirakeita, jotka toimitetaan valmistajille uusia autonosia varten. "autosta autoon" kierrätyskierto.