تواجه إعادة تدوير البلاستيك تحديات شديدة متعددة الأوجه. فالتلوث البلاستيكي يتراكم بشكل كبير، وتتفاقم آثاره بمرور الوقت. ويؤدي كل يوم من التقاعس عن العمل إلى تصاعد التلوث، مما يزيد بشكل كبير من تعقيدات وتكاليف المعالجة - مما يلحق ضررًا عميقًا لا يمكن إصلاحه على النظم الإيكولوجية وصحة الإنسان.

تواجه عملية إعادة تدوير البلاستيك تحديات مستمرة، بما في ذلك عدم كفاءة التقطيع/التنظيف، والتنقية دون المستوى المطلوب، وعدم الامتثال البيئي الكافي. إن تحقيق التنقية الفعالة وإعادة التدوير من الدرجة الممتازة أمر حتمي الآن لتقدم الصناعة.

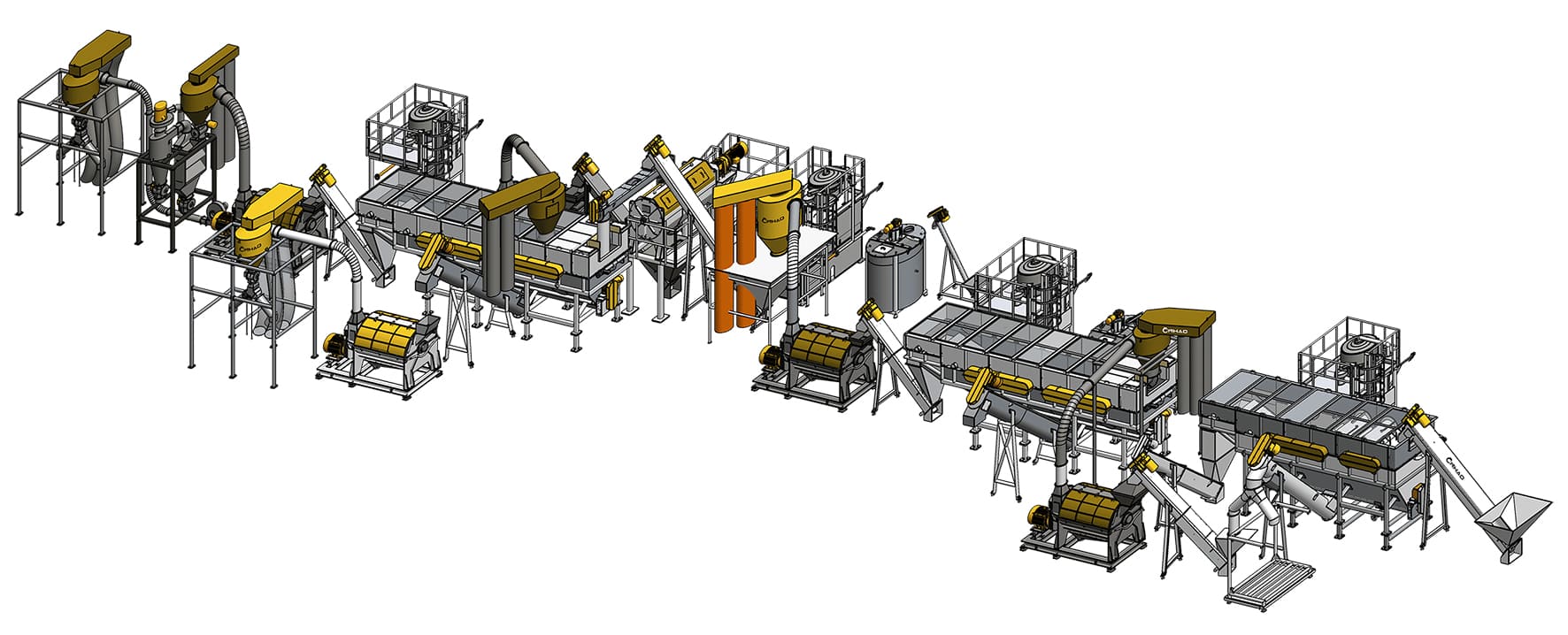

Streamline Eco Tech كشركة رائدة في مجال تصنيع المعدات المتطورة ومزود حلول الأنظمة للمشاكل الحرجة في إعادة تدوير النفايات البلاستيكية من خلال خط إعادة تدوير غسيل البلاستيك الصلب. من خلال الهندسة المدمجة والتخصص الوظيفي، يحول هذا الخط نفايات البلاستيك إلى نفايات بلاستيكية عالية القيمة لإعادة التدوير - وهو حل صلب لا غنى عنه لتمكين الاقتصادات الدائرية.

الميزات الرئيسية

- المعالجة الآلية المستمرة

تقدم البلاستيك الصلب المقطّع من خلال أنظمة ناقل/أنابيب متكاملة تتيح الأتمتة السلسة: الغسيل ← نزع الماء ← سير عمل التخزين. تقليل المناولة اليدوية مع زيادة الإنتاجية إلى الحد الأدنى. - التقسيم الوظيفي المعياري

معدات مخصصة (على سبيل المثال، التقطيع والغسيل ونزع الماء) مُحسّنة للوظائف الفردية، مدمجة في نظام استرداد عالي الكفاءة. - قدرة المعالجة للخدمة الشاقة

مصممة للبلاستيك الصلب (زجاجات PET، وحاويات البولي إيثيلين عالي الكثافة، ومنتجات PP/PS) مع بنية قوية تتعامل مع الشظايا عالية الصلابة وكبيرة الحجم. - ضمان التنظيف العميق

تنظيف متعدد المراحل (غسيل مسبق، غسيل رئيسي، شطف) مع عمل احتكاكي/حراري يزيل الزيوت والملصقات والملوثات. - تصميم الموارد المغلقة الحلقة المغلقة

مياه الغسيل المعاد تدويرها عبر أنظمة الترشيح (معدل إعادة استخدام 85%+)؛ الرقائق المعالجة تغذي التكوير مباشرةً لتدفق الموارد الدائرية.

المعدات

| المعدات | الوظيفة |

| كسارة | الاختزال الأولي لحجم الزجاجات الكاملة/البلاستيك الصلب إلى رقائق موحدة. |

| غسالة الاحتكاك | ملصقات تجريد الاحتكاك بين الدوار والماء عالي السرعة والحصى/المواد اللاصقة. |

| خزان الحوض العائم - الحوض العائم | الفصل المستند إلى الكثافة للرقائق مقابل الرواسب (المعادن/الحمأة)؛ التقليب الاختياري بالهواء. |

| خزان الغسيل الساخن | ماء ساخن + منظف يذيب الزيوت/البقايا العضوية. |

| جهاز طرد مركزي لنزع الماء عالي السرعة | التجفيف بالطرد المركزي (محتوى الرطوبة <10%). |

| صومعة التخزين | تخزين مخزن مؤقت للرقائق المنظفة قبل التكوير/التعبئة. |

| الناقل | النقل الآلي للمواد (سيور/ناقلات لولبية). |

نظام تكوين إضافي اختياري إضافي

- فرز الشوائب: فواصل مغناطيسية (ما بعد التقطيع) للمعادن؛ فواصل ضوئية تزيل الرقائق غير الملونة.

- نظام معالجة المياه: يحقق الترسيب/الترشيح متعدد المراحل معايير إعادة استخدام مياه الصرف الصناعي.

- التحكم الآلي: لوحة PLC مركزية لضبط درجة الحرارة، وعدد الدورات في الدقيقة، وبدء تشغيل الماكينة وإيقاف تشغيلها، وحجم المياه لضمان استقرار النظام.

يجسّد هذا الحل على نطاق صناعي الابتكار في الحلقة المغلقة - حيث يحول النفايات البلاستيكية الصلبة إلى مواد وسيطة ممتازة مع تقليل الآثار البيئية.