Kunststofffolien, ein wichtiges Material in der modernen Industrie, werden in großem Umfang für die Herstellung von Verpackungsfolien, Plastikverpackungen und gewebten Beuteln im Verpackungssektor sowie für Mulchfolien und Bodendecker in der Landwirtschaft verwendet. Branchenstatistiken zeigen, dass der weltweite Jahresverbrauch an Kunststofffolien 50 Millionen Tonnen übersteigt. Während Kunststofffolien die Produktionseffizienz in allen Industriezweigen steigern, führen ihre hohe Verwendungshäufigkeit und kurze Lebensdauer zu schwerwiegenden Umweltgefahren durch Abfälle. Die herkömmliche Deponieentsorgung verschwendet nicht nur Bodenressourcen, sondern setzt auch jährlich etwa 8 Millionen Tonnen Mikroplastik über ökologische Ketten in Meeressysteme frei. Wissenschaftliches Recycling und Ressourcennutzung sind zu dringenden Prioritäten geworden.

Derzeit führen Herausforderungen wie das geringe Gewicht, die geringe Dichte, das sperrige Volumen, die hohen Transportkosten und der hohe Gehalt an Verunreinigungen bei Kunststofffolienabfällen zu hohen Vorlaufkosten für das Recycling, was die Einrichtung eines effektiven Recyclingsystems behindert. Folglich werden Kunststofffolienabfälle als geringwertige Wertstoffe eingestuft, von denen viele letztendlich weggeworfen werden.

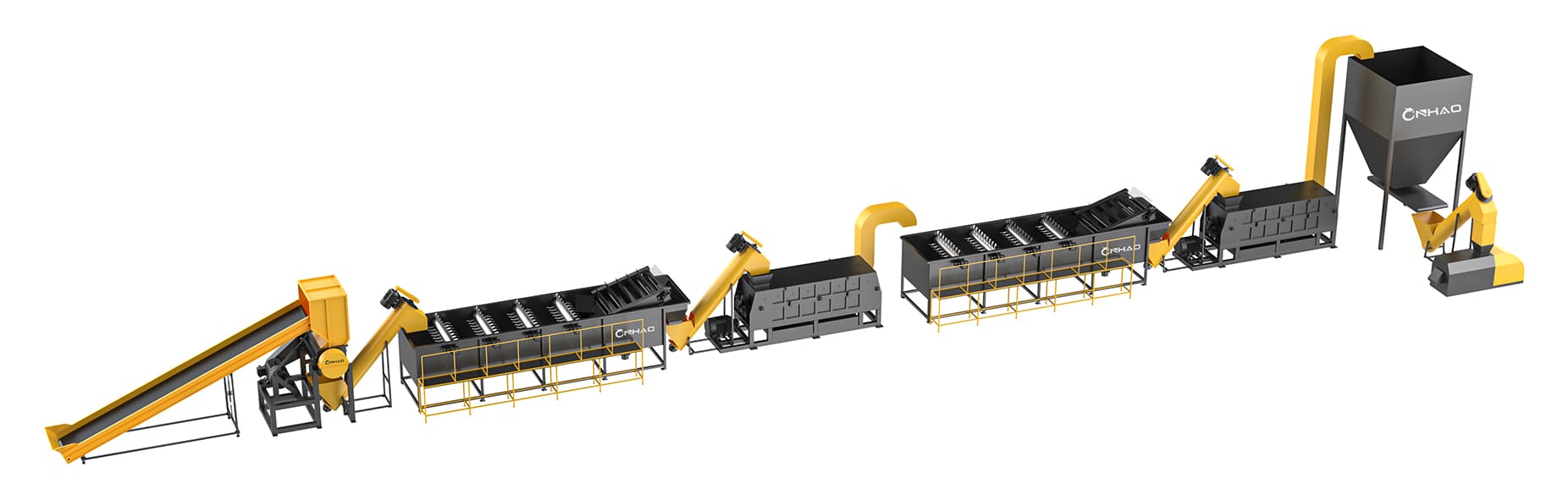

Stromlinie Eco Techist auf die Reinigung, Granulierung und Modifizierung von Kunststoffabfällen spezialisiert und hat sich zum Ziel gesetzt, hochwertige Produkte aus recyceltem Kunststoff herzustellen, die internationalen Standards entsprechen. Das unabhängig entwickelteAbfall Recycling von Kunststofffolien und Reinigungssystemist in erster Linie für die Verarbeitung von PE-Folien konzipiert, die mit Etiketten, Papierresten und geringen Mengen an Sand und Schlamm verunreinigt sind (z. B. Industrieverpackungen, Verpackungsfolien). Der Prozessablauf der Anlage umfasst:

- Zerkleinerungsmodul→Modul Reibungsreinigung→Modul Entwässerung→Modul Feinzerkleinerung→Modul Granulierung.

Durch die Nachbearbeitung erhält das Endprodukt eineFeuchtigkeitsgehalt ≤7%und ermöglicht eine effiziente Kreislaufverwertung von Kunststofffolienabfällen.

Die Kernausrüstungen, die durch jahrelange Erfahrung mit integrierten Systemen und die interne Forschung und Entwicklung von Streamline Eco Tech optimiert wurden, gewährleisten einen stabilen und hocheffizienten Betrieb und garantieren die Produktion von qualitativ hochwertigen Produkten. Diese Innovationen unterstreichen das Engagement des Unternehmens, nachhaltige Kunststoffrecyclingtechnologien voranzutreiben.

Die Brecher (C-Serie) eignet sich für die Zerkleinerung von Kunststoffen, Kabeln und Gummiprodukten. Es werden Hochgeschwindigkeitsmesser zum Schneiden verwendet, die eine ausgezeichnete Zerkleinerungseffizienz bieten. Sie wird in der Regel für die Nachzerkleinerung verwendet. Die Ausgangsgröße des Granulats kann durch das Siebgewebe eingestellt werden.